Metal Fabrication & Machining

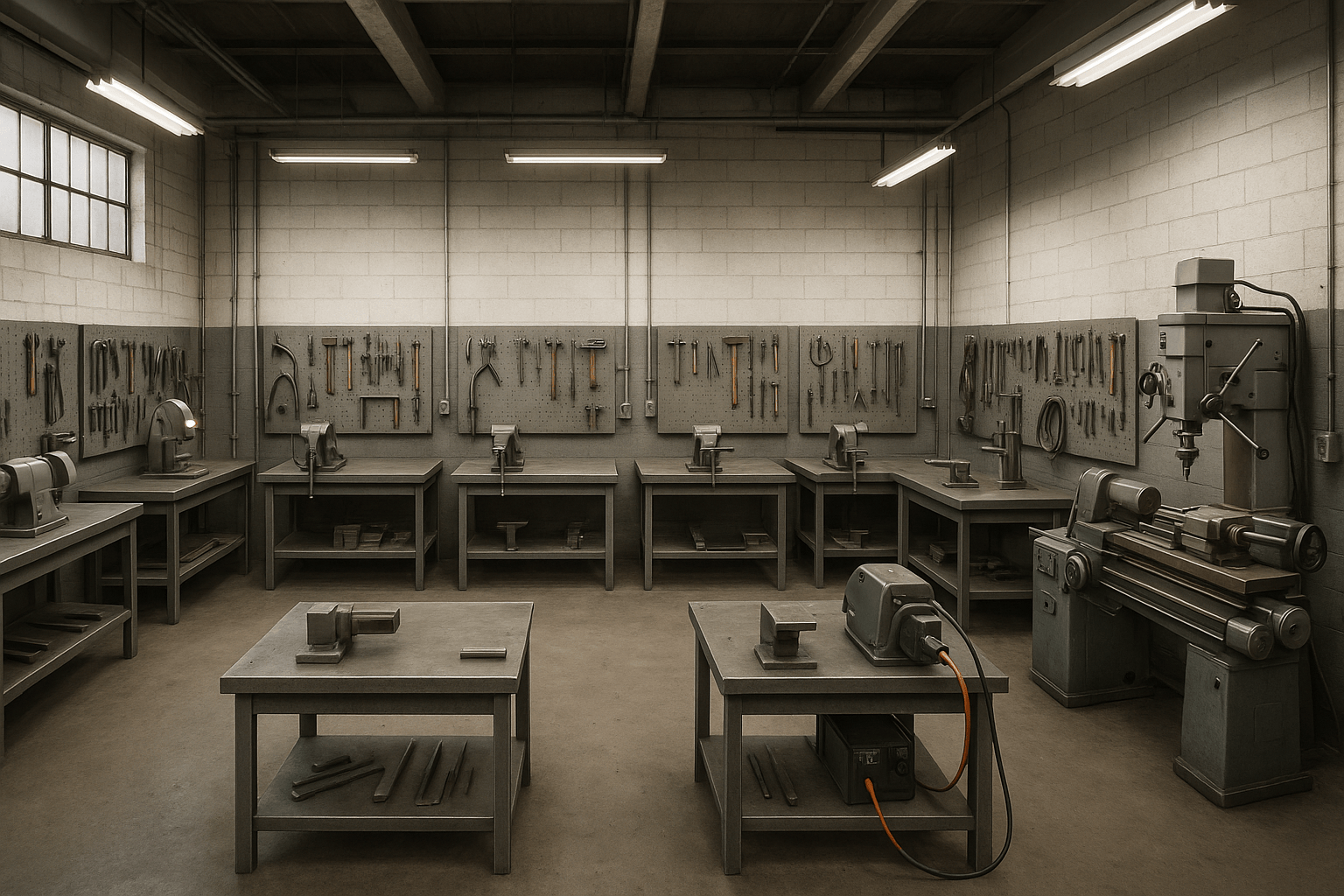

🔩 Metal Fabrication & Machining – Level 3 Course Overview

>This program equips students with the practical skills and theoretical knowledge required to fabricate, shape, and assemble metal components using hand tools, power tools, and precision machining equipment. It prepares learners for careers in manufacturing, construction, engineering maintenance, and metal workshop operations.

- Understand technical drawings and blueprints used in fabrication and machining

- Master the safe use of hand tools, measuring instruments, grinders, and cutting tools- Operate and maintain metalworking machinery, including: Lathes (manual and semi-auto), Milling machines, Drilling machines, Shapers and surface grinders

- Perform precision machining processes: facing, turning, threading, boring, and slotting

- Apply welding techniques (MIG, TIG, Arc) for assembly and joining

- Cut, bend, and shape metal plates, bars, and tubes using fabrication tools

- Apply finishing processes such as deburring, surface treatment, and painting

- Follow industrial safety practices, PPE protocols, and workshop ethics

Hands-On Projects May Include: • Project 1: Fabricate a small toolbox or metal stool using cutting, bending, welding, and finishing methods. • Project 2: Machine a shaft or threaded rod to specified tolerances using a lathe. • Project 3: Design and fabricate a welded frame or structural bracket. • Project 4: Complete tolerance testing and surface finish measurement using vernier, micrometer, and dial gauge.

Embrace the support and resources available to you and watch as your potential unfolds before your eyes. Seize each opportunity to learn and grow, pushing the boundaries of what you thought possible. With dedication and perseverance, you will not only achieve your goals but also inspire others to embark on their own journeys of self-discovery and success.